Dec 26, 2019Container-grown greens go commercial

Container-farmed greens took one small step closer to humankind on Sept. 30, as a large west Michigan foodservice distributor and a Brooklyn, New York-based urban ag startup announced a partnership.

Square Roots showed off basil plants growing vertically in shipping containers on the campus of Gordon Food Services’ Grand Rapids headquarters.

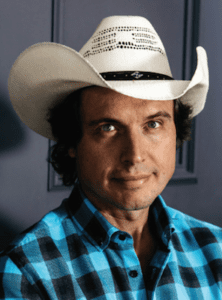

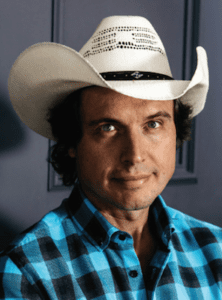

References to space travel were rife throughout the event. Square Roots co-founder Kimbal Musk, was in attendance the same day his brother – famed entrepreneur Elon Musk – was making national headlines for talking about rocket travel to Mars. A drone hovered overhead during a presentation on the container farms. During a Q&A, somebody asked a cheeky question about NASA’s interest in hydroponic growing techniques.

But really, it was all about the food and the growers.

The very best basil

Kimbal Musk said he couldn’t wait for attendees to try the basil grown on the farm.

“What we’re able to do with our technology on our campus here is recreate a climate we found to be perfect for basil,” he said. The climate the farms are emulating is that of Genoa, Italy, where the herb originated.

“We actually found a season in 1997, where all the chefs said this is the best basil that they remember eating,” Musk said. “We went back and looked upon that year, and we found when the sun came up, what time the sun set, and what was the humidity in that area, what was the carbon dioxide like, what was the oxygen like, and we were able to recreate that in these farms.”

Musk said he started cooking for his family at age 12 in South Africa. Although he went to Silicon Valley and learned to start software companies, he said his passion has always been food.

From growers to Gordon

The partnership with Gordon Food Service was exciting because it linked real growers with consumers, Musk said.

“We can harvest this in the morning and get it to someone’s plate by lunchtime – that’s the kind of innovation that Gordon Foods represents and we are absolutely thrilled to be partners with you guys,” he said.

The crops the farm is set up to grow are mint, chives and basil. Ten container farms on a two-acre lot are estimated to grow more than 50,000 pounds of premium herbs and greens per year – what Gordon Food Service estimates as the equivalent of a traditional 50-acre farm. The herbs will be sold to foodservice customers throughout Michigan, northern Indiana and Ohio, with a SquareRoots label on the packaging.

Photo: Gordon Food Service

“It’s absolutely more than a demonstration project, in that we’re able to bring a new solution, a new product to customers at scale,” said Gordon Food Service President and CEO Rich Wolowski. “We want to do something that can succeed, and we do think that this product, this farm, this model is something that we can take to all our markets.” The two companies have ambitions for additional indoor farms on or near Gordon Food Service’s more than two dozen distribution centers across Canada and the eastern U.S.

Employees on the farm work for SquareRoots, Wolowski said. The herbs will be harvested year-round and packaged at the farm site, and picked up by a truck to a distribution center three miles away, he said.

Growing in three dimensions

Square Roots co-founder and CEO Tobias Peggs walked event attendees through the operation of the vertical hydroponic growing system.

“We’re growing food in three dimensions rather than two dimensions,” he said.

Plants nestle in vertical towers of media, sipping a nutrient solution that trickles down each tower and is collected at the bottom, re-used in a closed-system loop. LEDs feed a prescribed spectrum of light to the plants.

“Through clever use of space, clever use of water, clever use of energy you’re able to grow quite a lot of food but (with) very few resources,” Peggs said. The biggest cost is labor – the pods are tended by a cohort of growers in Square Roots “Next-Gen Farmer Training Program” – a paid, full-time, year-long commitment for about 10 people.

Peggs said the nutrient solution contained traditional agricultural inputs: Nitrogen, phosphorus and potassium. Germinating seeds and seedlings are fed more red- and blue-colored light spectra.

Wired and weedless

Peggs said it was the software that set Square Roots apart from similar-looking container farms – the software sets the climate environment for the farms but uses an app to guide the growers through their day-to-day routines.

“The final part of the software is the analysis, where it’s looking at, ‘What did those farmers do inside those climates, and what can we learn?’” he said. Climates and growing techniques that work in one “farm” – be it in one of Square Roots’ 10 containers in Brooklyn, or one of its 10 containers in Grand Rapids – can be quickly tried at others in the network.

“These farms are all cloud-connected,” Peggs said. “As the network of farms gets larger, it gets smarter.”

Square Roots System Farm Manager Elias Zimmer said he had previously worked on Michigan State University’s Tollgate Extension Farm, an organic operation, as a full-season apprentice who pulled a lot of weeds by hand. He then committed to a Square Roots Next-Gen Farmer Training Program in Brooklyn as a way of furthering his career as a grower.

The hydroponic operations are not strictly speaking organic farms, but neither do they use pesticides or herbicides.

“Everything that you love about organic, this is too,” Zimmer said. He admitted he missed being outdoors, but there are other attractions to indoor growing.

“One of the positive things was no more weeding – a super-wasteful, monotonous task that nobody enjoys doing,” he said.

— Stephen Kloosterman, associate editor