Sep 9, 2020Food safety research enhanced by produce industry

Growers need not wait on the government for timely guidance to food safety questions or concerns.

That’s what industry veteran Victor Smith sees as one of the biggest benefits of the Center for Produce Safety (CPS). The Woodland, California-based nonprofit group in just 14 years passed on $30 million from growers and retailers to fund produce-specific safety research from researchers around the globe.

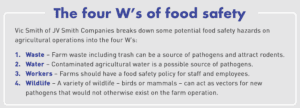

A large-scale grower-shipper of vegetables, JV Smith Companies has used the service a couple of times to promptly determine risks to food safety – one proved that dogs or coyotes in a field could be a vector for pathogens. And Smith continues to sing the praises of the organization in a new role as president of the nonprofit’s board of directors.

“It’s become, in my humble, possibly-biased opinion, the place, where if you have a food safety problem or concern, and you need knowledge, the Center for Produce Safety should be the first place you look,” Smith said. The organization continues to build past research to create a body of knowledge guiding the industry through potential pitfalls. “It’s ever-evolving and it’s very responsive to issues anywhere in the industry. I’ve seen CPS be so nimble and so responsive.”

Filling an industry need

Produce, of course, presents special food safety concerns because there’s no natural “kill step” for pathogens, such as cooking or pickling, that occurs before the fresh fruits and vegetables being sold.

CPS was initially formed in 2007 in response to an E. coli illness outbreak that government officials linked to bagged spinach. Packaged salads company Taylor Farms and Produce Marketing Association provided substantial seed money to form the nonprofit research organization. Since that time, the CPS’ research interests have broadened to include apples during the 2014 Listeria monocytogenes illness outbreak linked to candy apples, and even some research for pistachio and almond growers, Smith said.

“Grants are given based on how relevant and how severe the potential problem is,” he said. “I guarantee you, the critical projects are funded.”

In the wake of the 2018 outbreak of E. coli infections that were linked to Romaine lettuce, agricultural water contamination has become a key topic of interest. In the 2018 investigation, officials from the U.S. Centers for Disease Control, the FDA and state authorities found the same bacterial strain from the outbreaks in an agricultural water reservoir.

“That’s a problem wherever you go,” Smith said. “Anything you can learn about pathogen transfer from water sources is extremely important. CPS has done a lot of work in that arena, really focused on leafy greens, but going in other directions, too. But a lot of the research has focused on leafy greens, and there’s no doubt we need it, because we’re growing out in an open environment, in the good, old fresh air of nature. And so we’re subject to more potential risk.”

The Food Safety Modernization Act’s Produce Rule in recent years updated standards for growers nationally, but Smith said that large growers in the produce industry itself are far beyond the minimum requirements of the rule. And CPS sponsors new research needed, becoming – he said – not “a source” but “the source” of research in the field.

CPS awards grants to researchers internationally as well as at U.S. land-grant universities. The researchers are required to publish the research in a timely fashion, Smith said. CPS publishes its research findings annually, and they are online.

Working with companies

CPS works with individual produce companies on research, and JV Smith Companies has twice donated to group to support projects. One study that JV Smith donated toward found that stray dogs and coyotes are possible vectors for certain strains of E. coli.

In response to the Romaine lettuce-linked outbreak, Smith’s company donated two separate 3-acre “blocks” or fields where researchers could replicate large, at-scale Romaine lettuce production and harvesting for their experiments.

“Certain plants, they got harvested and then put on this machine – the transfer belt – and then went up the incline belt and into a chute, where the product itself would fall into the field bins,” Smith said. “We found a critical point where it went up the belt and into the chute where we found pathogens there consistently and knowing we had cross-contaminated from prior plants being harvested. Plants that were healthy and had been harvested on the same machine got cross-contaminated at a particular point, which was fascinating. It was a good finding.”

Oddly enough, the food safety field has remained relatively quiet during the global pandemic. As a vector for the COVID-19 virus, food remains “low risk,” Smith said.

“So far, we’re not aware of any transference of the virus to humans by food,” Smith said. “The pathogen’s transferred by droplets from the respiratory system – a cough or a sneeze … that’s the biggest risk.”

A group for growers

Although CPS has significant involvement from retailers as well as growers, Smith stressed the growers are heavily involved – and growers have and continue to work with retailers on food safety issues.

In a news release announcing the change, Corsi was complimentary about his successor.

“Vic is the type of guy that doesn’t take no for an answer,” Corsi said. “Instead, he asks, ‘Why can’t we?’ That attitude has earned him widespread respect in the industry.”

Add to that attitude a position as a large-scale grower-shipper of vegetables for packaged salad producers and large-scale vegetable shippers. JV Smith Companies grows crops year-round in four different areas, including 22,000 acres split between Yuma, Arizona and Baja, Mexico. It also has about 11,000 acres in the Salinas area and 3,000 acres in south central Colorado. The crops include commodity-like vegetables such as celery, broccoli, cauliflower and green onions; in addition to greens such as iceberg lettuce, Romaine and baby arugula.

“We try to bring all those different operations in different states together and try to create a synergy of the knowledge and experience, and the customer base, to be relevant to all of our major customers,” Smith said.

Regardless of size, all growers should be aware and up-to-date on food safety concerns.

“Anybody that’s producing food and entering the food supply chain should be very concerned,” Smith said. “The old days of ‘Well, we’ve always had cattle around the hills and we’ve always grown vegetables in the valley, and we’ve never had a problem’ – those days are gone.

“If you want to sell it to a retailer, you better have a food safety program in place,” he said. “If they’re limiting themselves to farmer-market-type scenarios, then OK, you still don’t want to poison anybody, don’t want to hurt anybody. You could still have an impact on a group of people, albeit not a multi-state outbreak.”

— Stephen Kloosterman, associate editor