Jul 7, 2020OSU professor shares benefits of controlled-environment berries

Substrate-based strawberry production under controlled environment (greenhouse, high tunnels) is a fast-growing sector in North America. Along with the increasing interest in local production, several greenhouse industries as well as traditional field producers in North America began to produce strawberries under controlled environments.

Chieri Kubota, professor in the department of horticulture and crop science at Ohio State University (OSU), shared her insight into controlled-environment strawberry production during a presentation at the 2020 Mid-Atlantic Fruit & Vegetable Convention in Hershey, Pennsylvania.

Kubota worked as faculty for six years in Chiba University, 16 years in the School of Plant Sciences at Arizona State University and joined the faculty at OSU in 2017. Her research includes value-added CEA crop production, vegetable grafting, hydroponic strawberry production, as well as LED lighting applications.

Kubota said berry production under controlled-environment has taken hold in California, Michigan, New York, Ohio and Tennessee, along with growers in Canada and Mexico.

Ohio’s controlled-environment agriculture area tripled from 2012 to 2017, according to the USDA.

“It’s a niche market for urban food systems, (generating) a higher price point,” Kubota said. There also has been a push from grocery stores and encourages year-round production.”

The practice also holds potential for possible winter urban ag tourism, Kubota said.

Production systems range from Dutch-style Venlo greenhouses (for year-round production) to single-layer polyethylene tunnels with “table top” production systems (for extended seasonal production) of strawberries in the United States.

Complete information on the basics and applications of growing strawberries under controlled-environment can be found on OSU’s indoor-berry website www.u.osu.edu/indoorberry.

Planting materials, cultivars

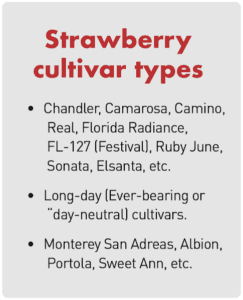

Strawberry is vegatatively propagated, typically with daughter plants developed in runners (stolons). Cultivars are classified as June-bearing type (short-day plant) and ever-bearing type (facultative long-day plant). Cultivars conventionally classified as “day-neutral” type also behave like facultative long-day plants.

There are a number of “seed-propagate” strawberry cultivars, although their commercial applications are still limited, Kubota said.

There are various types of transplants available for strawberry production. They are bare-rooted frigo plants, fresh dug plants, runner tips, rooted runner plugs and tray plants. However, off-season producers have relatively limited options in North America, due to the fact that availability of specific types of planting materials are seasonal and optimized for existing open-field cropping systems.

Also, growers new to strawberry production must understand that many cultivars available in North America are proprietary, which requires an appropriate license agreement to propagate even for their own usage. Therefore, growers need to purchase plants from a nursery that carries the propagation license of the selective cultivar.

Production systems

Controlled-environment structures for strawberries grown commercially use distinct types of structures, including:

• High tunnels (AKA table-top systems).

• Greenhouses, unheated.

• Greenhouses, heated.

• Indoor farms (without sunlight).

• Soilless substrate-based production system with drip irrigation is the most widely used production system commercially. Productivity seems to be limited in water-culture-base production systems. Regardless, production systems are designed so that workers stand instead of bending over the crops, improving worker efficiency.

Soilless-substrate-based production systems using a simple raised gutter supported by a leg structure anchored in the ground is called a “table-top system.” They are typically placed inside a simple structure such as rain shelters or high tunnels. This system is widely used in Europe and is slowly being introduced in North America.

In temperature-controlled Dutch-style greenhouses, use of steel hanging gutters to those used for high-wire production is common. A typical spacing between gutters is 3.3 feet (center-to-center), shorter than a standard high-wire spacing (5 feet). Placed on top of the gutters, containers and bags filled with soilless substrates are irrigated with drip-irrigated systems.

Substrate, nutrient solution

Kubota said strawberry plants are sensitive to root zone environment (physical and chemical environment). Their roots do not develop well when inappropriate substrate is used or moisture content is not managed well. Strawberry fruit yield is therefore largely affected by substrates and resulting rootzone conditions.

Physical characteristics interact with container geometries. This means that substrate optimization/selection must take a whole-system approach. Optimizing substrate physical, chemical and biological properties can increase the overall yield of strawberry by 30% in an OSU study.

When pre-mixed substrates are used, it is important to understand that what is an optimum substrate depends on the climate conditions (potential transpiration), container systems (column height and drainage design) and source water quality (e.g., alkalinity).

Irrigation

Irrigation (fertigation) is a key management technique in high-quality strawberry production.

Kubota said OSU typically uses a Japanese nutrient formula that has relatively low nitrogen concentration (77-100 ppm with 90% in nitrate form). Electrical conductivity is maintained at

1.0 dS/m and PH is adjusted between 5-6.

“Strawberry plants require good porosity and drainage to assure good oxygen availability in the root zone,” she said.

Environment, benchmark conditions

Response to specific cultivars need to be examined on site, rather than simply applying general literature-based information – especially those cultivars that are bred for and cultivated in open fields for which there is little information regarding responses to individual environmental factors (and their interactions).

Greenhouse-controlled environments allow independent control of photoperiod, light intensity and temperature among other factors, and thereby potentially control the plant growth and development to maximize the crop productivity and fruit quality.

When all conditions are at optimum ranges, strawberry production is highly correlated with light and plants seem to produce 2-3 grams of fruit per every addition of one mole of photosynthetic active radiation (mol m-2).

With good light and optimum environment, benchmark yield can be 700 grams to 1 kg (1.5 to 2.2 pounds) of fruit per plant over 6-7 months of off-season production (e.g., early November to May.)

Productivity is also dependent on the cultivar. However, highly productive cultivars tend to have less flavorful fruits (lower Brix or soluble solid concentrations).

— Gary Pullano, managing editor