Dec 6, 2017Container farming: grower brings crops to community

The farm of Brian Harris measures just 350 square feet, and its crops are hidden from the sun.

Harris is practicing Controlled Environment Agriculture (CEA) in an insulated shipping container, where he said he’s able to grow as many leafy greens as a 1.5- to 2-acre farm.

Harris said he’s hoping to demonstrate the future and possibilities of CEA and urban agriculture in Grand Rapids, Michigan, where his operation, Green Collar Farms, sits in an empty lot.

“This is a demonstration space,” he said. “I think what a lot of people don’t understand is how hydroponics works.”

How it works

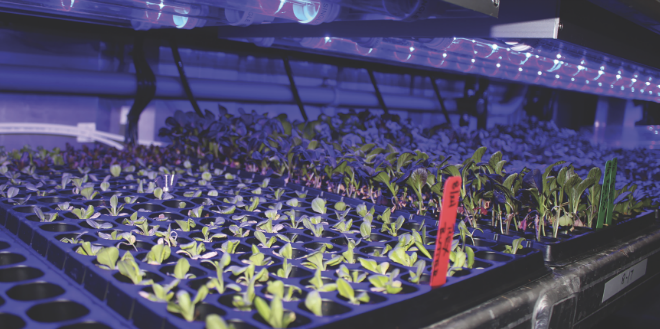

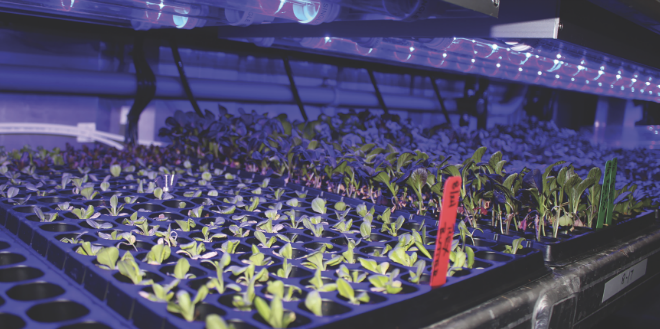

Pelletized seeds germinate in moistened pockets of ground-up coconut husk in trays on a countertop. The plastic trays are then transported to a nursery, another tray that floods twice daily with the nutrient-laced water. The nutrient water is delivered at the base of the plant’s root ball in coconut husk.

From there, the seedlings are transplanted into the vertical section of the farm, hanging in what looks like plastic beams hanging from the ceiling of the shipping container. Each beam has a hard-plastic shell, plastic foam sides that hold the root balls in place, and a felt strip lining that delivers nutrient water from a dedicated nozzle in the ceiling of the shipping container.

The plants are lit by strips of LED lights – in the vertical section of the farm, the double-sided strips hang down between the beams. Because plants don’t see the same spectrum of light that people do, the light for the plants is reds and blues.

“LED technology has really helped a great deal in being able to introduce the exact spectrums of light,” Harris said.

Light emitting diodes shine blue to simulate the sun’s morning spectrum, “waking up” the plants, Harris said. Two hours later, the light changes, producing a magenta light that the plants will soak up for about 12 hours. At the end of the plant’s day, the blue lights kick off, leaving just the red – a photo signal, Harris said, so the plants can prepare to settle down from the night.

The air they breathe is modified, too – enriched with CO2 via a propane burner. A fan keeps the CO2 from settling at the bottom of the container.

The air’s CO2 level, like the lights and nutrient water, is regulated electronically. Excess nutrient water is returned to a tank at the back where it is monitored for pH and levels of sulfur, magnesium and nitrogen; pumps push more nutrients and water into the tank as needed. In giving a demonstration of the farm, Harris used an electronic panel on the side of the container. After hours, he said, the system will push notifications to his phone if something goes amiss.

Of course, the plant’s daytime is subjective because it’s cut off from the sun. Harris has them grow during the night because electricity is cheaper during the off-peak hours.

What it can grow

Harris said that it’s possible to grow tomatoes, strawberries and soft fruit in a CEA environment. But he’s not saying that CEA is the end of traditional agriculture. Rather, it complements traditional agriculture.

“There are field-appropriate crops,” he said. “You’re not going to grow wheat indoors. This is not an apple orchard. You’re not going to float cranberries here.”

But, he said, many types of consumer crops – in his case, herbs and leafy greens – don’t need processing and can be grown locally rather than shipped into the city. CEA uses 90 percent less water, he said, and because it’s a closed environment, there’s no need for fungicides or pesticides.

Hydroponics plants grow only about 12 percent of the size of a root ball as a traditional plant, Harris said, enabling the plant to spend more of its nutrients growing in the other direction. In his opinion, it leads to better flavor and texture in greens like Blue Scotch kale and spicy arugula.

The control over the agriculture leads to consistently-sized plants.

“The product reliability and consistency is there, and the chefs seem to appreciate that,” he said.

Midwestern restaurants typically rely on California-grown romaine or iceberg lettuce, during the winter, but without the limits on the growing season, Harris is also able to grow a wider variety of greens, offering up butterhead-type Oakleaf lettuce, and Deer Tongue lettuce, in the off season. He’s also able to grow a visually magnificent purple strain of pak choi, called Royal Choi – grown in CEA, he said, the specialty crop is tender enough to be served in a salad without being sautéed.

Future use

CEA shipping containers have been cropping up across the U.S. in part due to several firms in North America outfitting old containers and selling them as turnkey operations to growers. Harris said he had done CEA farming in his basement prior to buying his own operation. Harris bought his for about $90,000 – he had the money from selling a steel company he owned.

Harris’ container holds 256 of the vertical beams or towers, or about 4,000 plant sites. He said he’s hoping to receive a second container for growing herbs. In a couple years, Harris would like to be running a 10,000-square-foot CEA operation – the equivalent of a 60-acre vegetable farm. “That’s real jobs,” he said.

But first he’s trying to prove the concept to the community. So far, he’s been giving the greens away to churches, food kitchens and visitors. What he hopes to do soon is grow a specific supply for a few restaurants.

“This is a nascent industry,” he said.

— Stephen Kloosterman, assistant editor