Apr 1, 2022Agronomic practices, sustainability fuel Parker Farms’ 50 years

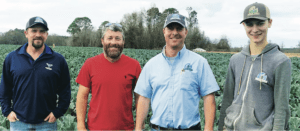

As it nears its golden anniversary, E.A. Parker & Sons LLC, which does business as Parker Farms, prepares to transition from third-generation family ownership to involvement of the younger generation.

Careful crop selection, use of agronomic technology to control costs and battle inflation and commitment to sustainable growing practices are important parts of success for the Oak Grove, Virginia-based grower that grows and ships vegetables from throughout North America and Central America.

East Coast empire

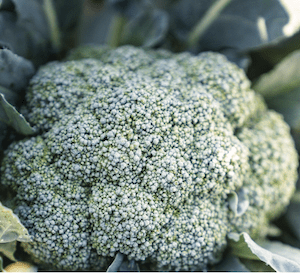

The nearly 50-year-old Parker Farms grows broccoli, sweet corn, yellow squash and zucchini squash, asparagus, bell peppers, eggplant and cucumbers.

Parker Farms’ growing regions strech up and down the East Coast, from Florida to New York including stops along the way in Georgia, South Carolina, North Carolina, Virginia, Pennsylvania, New Jersey and New York and Indiana. During the winter, Parker Farms sources product through relationships with growers in Mexico and Honduras.

In addition, Parker Farms partners with a dozen major growing operations in other regions, including Tunnell Farms in Swanquarter, North Carolina, BG Williams Farm in Uvalda, Georgia, and Old Dominion Organic Farm in Dundas, Virginia.

Organic growth

Organics continue to become a larger commodity segment. Though they comprise less than 10% of Parker Farms’ sales, organics are expanding in demand and supply.

“Organics continue to show a lot of interest from retailers,” said Sean McFadden, business development. “While it’s still a small percentage of sales, it is an actively growing percentage.”

Storm clouds of inflation and other rising consumer costs could threaten organic movement.

“I am continually watching the squeeze on organic consumers due to inflation, as is costing them more these days,” said McFadden. “How long can American consumers continue to pay premium prices for organics given the inevitable cost increases? Certainly, there is a constituency that can and will always be willing and able to do so, but a lot of millennials, many of whom are on tight budgets, may have to cut-back on their organic purchases.”

RELATED: Organic is the future at Old Dominion Organic Farms

U-pick origins

The Parkers’ farming legacy goes back to the mid-1970s. In 1974, Admiral E.A. Parker and his sons Rhoderick and Christopher began a u-pick operation in Clinton, Maryland. E.A. Parker & Sons LLC, grew on 2 acres of vegetables and berries. Because of the expanding popularity of farmers markets and “pick your own” operations, within two years acreage ballooned to 150 acres. The Parkers also expanded into roadside marketing.

Due to rising demand, the Parkers by the latter years of the 1970s doubled their u-pick acreage to 300 acres, making the operation one of the largest East Coast u-picks.

During this time, wholesale and retail sales increased and eclipsed the u-pick and farmers’ market channels. In the late 1980s, the Parkers began expanding operations into the South, boosting acreage to 500, plus constructing a South Carolina packing and cooling operation.

By the late 1990s, Parker Farms was growing on 3,000 acres from north Florida to Delaware.

Changes in demand and production necessitated the addition and ending of some crops. While the Parkers were once one of the East Coast’s largest growers of greens, they transitioned out of that segment during the early 2000s and began growing broccoli. In 2010, the Parkers partnered with L&M Cos. to form Atlantic Fresh to provide year-round production of broccoli throughout the East Coast.

Blossoming broccoli

While broccoli has seen expansion in the eastern U.S., it remains a costly commodity to grow.

“There is an extreme learning curve in respect to growing practices,” said McFadden. “The infrastructure required to grow the crop, including the machinery, the equipment, the icing equipment, all those things can be a barrier to entering that crop on the East Coast. Our yields are not like those on the West Coast. Our unit costs are a little more per-box to grow. However, we have a significant freight advantage. All those things come together to make us somewhat competitive versus California and Mexico.”

Broccoli, sweet corn and squash are Parker Farms’ biggest-selling commodities. Adding crops or new regions isn’t taken lightly.

“It’s slow and steady that wins the race,” said Jimmy Carter, sales manager/partner. “We take our time in making decisions on going after new ventures, tasks and crops. We make sure we do as much research as we can.”

The Parkers remain committed to sustainability. Buffer zones along waterways, no-till practices and employing pest traps to determine the types of sprays required to protect the crops are valuable tools in preserving the land.

High-tech farming

Precision application employs computers and satellite technology to monitor fertilizer application. Large chunks of a field may receive fertilization while other parts that don’t require phosphorus or potassium may receive none, thus reducing costs.

“This is critical in our efforts to protect local waterways and reduce nutrient runoff,” said Carter.

“People say farmers spray too much,” said Carter. “No farmer wants to spray or add fertilizer more than they have to, especially now with fertilizer costs up 300%.”

All of Parker Farms’ planting tractors and sprayers are equipped with GPS. Soil is sampled throughout the fields. Spray rigs can determine where to apply crop protectants and fertilizer based on soil analysis. Rafe Parker, Rhoderick Parker’s son, is exploring drone technology for crop protectant application.

Sustainable practices

Solar panels dominate the roof of Parker Farms’ large Oak Grove packinghouse and headquarters, providing 100% solar powering, except when electric demand outstrips what the sun provides. The solar cells allow Parker Farms to be 100% carbon neutral in its power consumption. The Parkers are looking to expand solar cells to other regions.

While a 40-yard capacity dumpster is used to transport packinghouse waste to landfills weekly, a six-yard dumpster now hauls wastage every other week, reducing landfill use by 80%.

“Parker Farms understands the delicate balance between sustainable and local food distribution,” said Carter. “We are dedicated to staying ahead of trends and ways to create solutions that offer the consumer the best possible product.”

Sustainability methods include reducing air pollution, avoiding consuming too much fossil fuels and water, retaining soil quality through preventing erosion and preventing the loss of biodiversity.

Commitment to sustainability remains crucial.

“There’s no greater person tied to the earth than the farmer,” said McFadden. “We are trying to improve on what we’re working with day in and day out. We are doing everything that can be done from a sustainability perspective.”

Countering costs

Escalating input costs remains the biggest challenge pressing all growers. The price of fuel, fertilizer, crop protectants, labor and many other critical components of farming increased at least 25%.

“This is truly a 100% make or break year for growers,” said Carter. “The risk exposure in regard to produce and input costs is so much greater this year.”

Parker Farms is renegotiating many contracts but is receiving pushback from its customers, who say they can’t pay the prices needed to efficiently grow vegetables.

“We are in a very contrarian dilemma now,” said McFadden. “Prices to the farm will have to go up or production will need to be cut back.”

To increase efficiencies and counter skyrocketing costs, Parker Farms researches technology.

“All implementation of technology is driven by costs,” said McFadden. “If we can do something that will shave money from input costs, we will try to adopt it as quickly as possible.”

Family future

Joe Parker, chief financial officer, and Rafe Parker, production manager, are the third generation partners managing the company. The newest generation attending agriculture schools and colleges is expected to begin working in the company full-time within three to four years. That fourth generation will help the Parkers carry on E.A. Parker’s legacy and treat its growers and customers as part of its tight-knit family.

“It’s knowing the company and family name have grown over the years, because of family involvement,” said Carter. “As we evolve as a larger grower, we will have to reach outside the core family structure to bring more specialized expertise into our operations.”

Despite the challenges, Parker Farms remains hopeful the future will bring good things.

“You have to be optimistic as a grower and a person in the vegetable business,” said McFadden.

“If not, you shouldn’t be in the business. There are a lot of challenges facing us. There’s probably no greater challenge we face as an industry than what we are in now. We hope to overcome those challenges and then move forward. To do that, we will have to figure out a lot of things this year in regard to marketing, cost inputs, basically, a total revisiting of the operation top to bottom to find any efficiencies we can.”

– Doug Ohlemeier, assistant editor