Feb 1, 2021Greenhouses trial new lighting controllers by Candidus

Greenhouse growers in several states this year are trialing a new way of fine-tuning one’s greenhouse lights for better crops – whether they be vegetables, ornamentals or even cannabis.

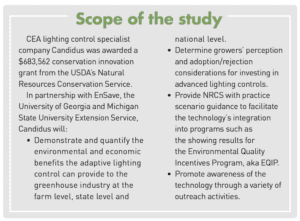

Athens, Georgia-based startup company Candidus received a conservation innovation grant of more than $680,000 grant from the USDA’s Natural Resources Conservation Service (NRCS) to study the use of its adaptive lighting control systems. The study will work with growers to gauge the environmental, economic and socioeconomic benefits to the system.

Light pollution is a common complaint of greenhouse neighbors, and energy costs also add up, so the system is meant to help growers use as little light as possible.

“On-farm trials help producers improve the health of their operations while at the same time helping NRCS build data to show the benefit of innovative conservation systems and practices applied on the land,” NRCS Acting Chief Kevin Norton said in a news release.

Candidus will conduct the study with the University of Georgia, Michigan State University Extension Service and EnSave, a Vermont-based sustainability solutions company.

Candidus founders Erico Mattos and Marc van Iersel understand the unique challenges of controlled environment agriculture. Mattos received a doctorate from the University of Georgia in 2013, and his research has focused on the use of LED lighting and electronic feedback mechanisms. Von Iersel has a doctorate in agronomy from the University Arkansas focusing on crop physiology.

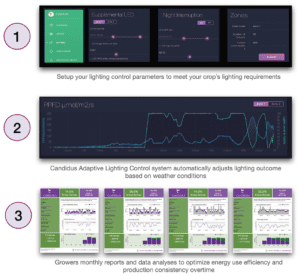

The system features a dimmable feature that turns the lights down to only the extent needed, as measured in microns. Another feature of the system is that it adapts to the weather as it occurs in realtime, instead of using fixed thresholds that are more common in the industry.

“Say a grower is growing lettuce, for example, and they have to achieve a DLI (daily light integral) of 17 moles,” Mattos said. “The system’s going to look into how many hours they had during the photoperiod, so let’s say they had 16 hours of light a day. And then the system calculates, if for 16 hours you maintain light levels at 300 micromoles, you get a DLI of 17. What happens is, as the sun comes to the sky, the sky becomes brighter, so let’s say for the first five hours of the day, you get much more light than 300 micromoles. And the remaining part of the day – the remaining 11 hours of the day – your threshold might not be 300 (micromoles) anymore, because you’ve got a lot of light. … So the system we make might say, ‘Well, you still have 11 hours. If you maintain the lights now at 200 micromoles, you can achieve your target DLI.’”

Mattos said the system will continue re-calculating a light threshold throughout the day.

“You’re never going to provide more light than you need,” he said.

Part of the study is to examine the economics and cost savings. Less light means not only less light pollution, but savings in energy costs – on its website, Candidus estimates a 33% energy savings or $20,000 per year per acre.

Mattos said a trial program with access to the software and hardware for three months runs about $2,500. A full installation of the system costs several thousands of dollars, depending on the size of the greenhouse.

“The technology’s very modular, so we use off-the-shelf components,” Mattos said. The software runs off small Raspberry Pi computers, controlling almost any commercial network of lights. Growers receive automatically-generated reports. “We can go anywhere from 20 lights and 2,000 square feet to tens of acres … we just add more hardware.”

The third aspect of the study is the socio-economic aspect of introducing new technology.

“When you introduce a new technology … there is a lot of resistance from the growers,” Mattos said. “We want to understand the thought process. What are the best ways to break the barrier, to better communicate with growers?”

The project will include 12 participating growers in Virginia, California and Michigan – different climates – and growing a variety of crops, to demonstrate some of the light controller’s benefits to different kinds of growers in different regions. In early December, he was still nailing down other growers to participate in the trial.

“For the USDA, we want to show them the efficacy of a new technology that can work nationwide,” Mattos said. “We don’t want a technology that solves just the problems of New York growers, or California growers. So, we make sure that these technologies are dynamic, can adapt to all the crops and can provide benefits to the entire greenhouse industry.”

— Stephen Kloosterman, associate editor