Feb 4, 2019Weather, varieties, labor keep Sundance Farms alert

Jacqueline Vazquez-Celaya believes she gravitated to the management of a 400-acre California strawberry growing operation through “dumb luck.” But her meticulous grasp of the challenges presented in her current role doesn’t match either of those words.

Vazquez-Celaya earned a business and marketing degree from college. It helped her land a position with Driscoll’s as director of partner operations.

“After about a month I started to get bored (in the office) and started going out to the fields once a week, and then twice a week,” she said. It soon became apparent that farm management was her calling, and she left Driscoll’s to become director of operations for Sundance Berry Farms in Moss Landing, California.

The operation markets its berry products to Costco, Walmart, Trader Joe’s and other significant retail outlets.

Sundance Berry Farms, which was founded in 2003, operates berry farms in three California growing districts: Oxnard, Santa Maria and Watsonville.

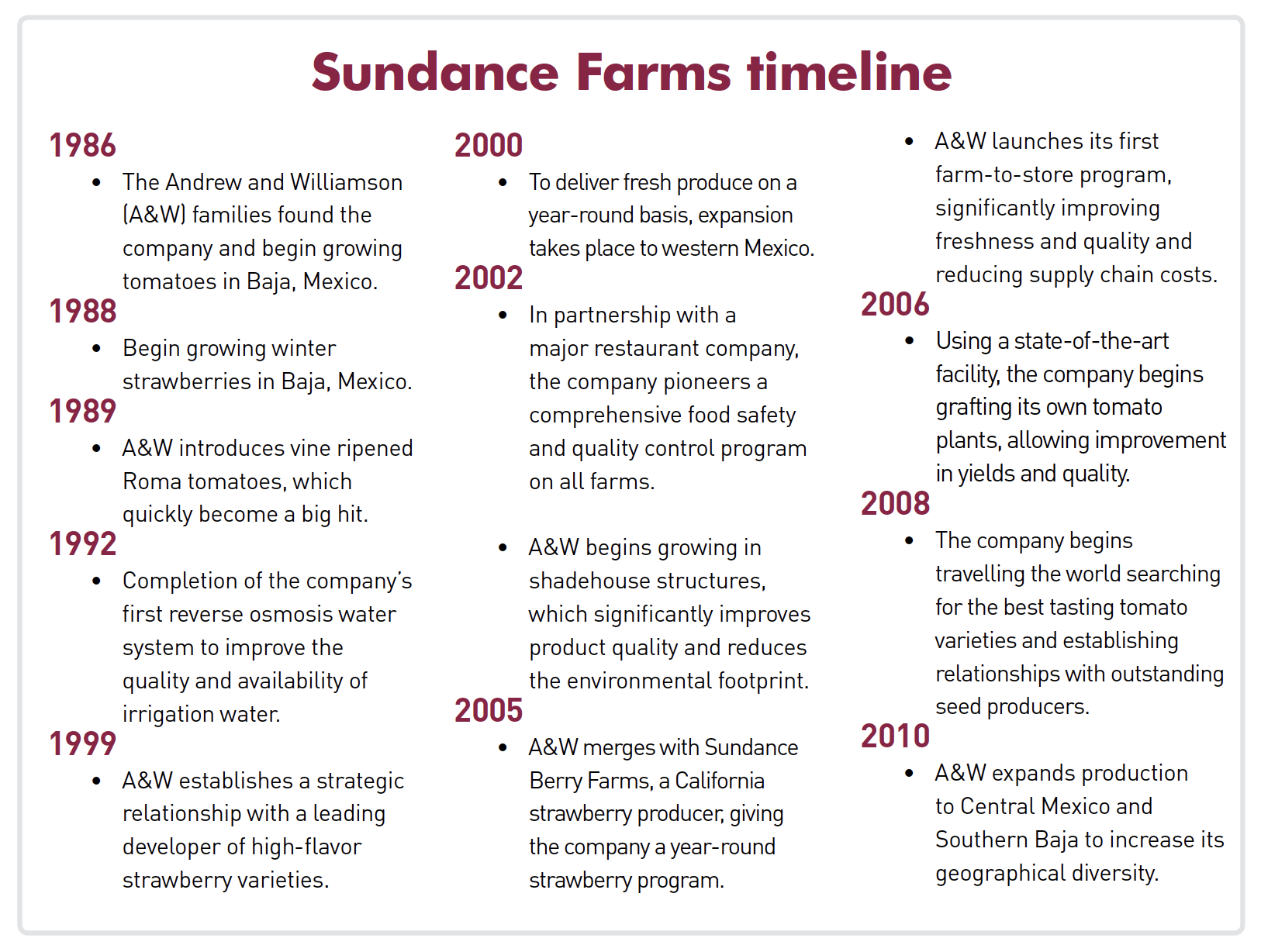

Sundance merged with Andrew Williamson (A&W) in 2005 in order to provide year-round strawberry production. In the partnership, Sundance focuses on the production side of the berry business, while A&W handles all sales and marketing.

Sundance’s production covers spring, summer and fall, with growing operations in the California strawberry growing districts of Coachella, Oxnard, Santa Maria and Salinas/Watsonville.

A&W is strong during the winter and spring as it sources strawberries from Baja California, Mexico.

Sundance’s Moss Landing location, situated adjacent to scenic Monterey Bay, was a tour stop on the North American Strawberry Growers Association’s (NASGA) 2018 Summer Tour.

Strawberry Growers Association’s 2018 summer tour. Photos: Gary Pullano

Having been a farm manager for over eight years, Vazquez-Celaya has had to expand her growing knowledge amid extreme variations influenced by Mother Nature.

“Two years ago, we finally got out of the drought in California, she said. “It was a long-standing drought. I never learned to grow in rain. No one taught me how to farm in rain. I’d only known ways to grow during an eight-year drought. I had to call on my contacts from Driscoll’s to come show me how to grow in the rain, like they helped me learn how to grow in a drought.”

Like most growers, she now prefers a balance of crop-friendly weather offerings.

“If it rains enough and it’s cold in December, it helps with management of the core group we employ in November,” Vazquez-Celaya said. “My preference is a little bit of both (rain and drier conditions). When it rains and Mother Nature does what it’s supposed to do, the plant responds. So, I like a little bit of rain when it’s supposed to rain, and, cold when it’s supposed to be. I like the seasons to be respected.”

Vazquez-Celaya readily shared her knowledge of strawberry varieties and how each performs in the production cycle.

“You learn about characteristics of certain varieties. Monterey is basically the workhorse. It’s a really strong plant, very high yielding. You’ll get a peak with Monterey, with lots of flowering in September.”

Monterey strawberry is a moderate day-neutral cultivar from California. It has great flavor, while being more tolerant to high summer temperatures. The plant has good leaf disease resistance, but is susceptible to powdery mildew.

Cabrillo is a newer day-neutral cultivar released from University of California-Davis. This is a moderately strong flowering variety that is adaptable to both winter and summer plantings. Fruit size and firmness is comparable to that of Albion, as well as San Andreas with greater individual plant yields and offers outstanding flavor.

Cabrillo is disease resistant to powdery mildew, verticillium wilt, phytophthora crown rot, as well as common leaf spot, and with proper treatment can be tolerant to two-spotted spider mite. But it is susceptible to anthracnose crown rot.

“Monterey will definitely out-yield Cabrillo,” Vazquez-Celaya said. “Cabrillo has a really firm characteristic to it that you really don’t see in the Monterey.”

She said Cabrillo is not as sweet.Monterey’s brix count – the sugar content – is “way higher” than the Cabrillo.

“With Monterey, we will get 8 to 12 brix,” Vazquez-Celaya said. “In a Cabrillo, we’re lucky to do 6 to 8. But Cabrillo really helps with our peak.”

Plant spacing is variable in Sundance Farms’ fields.

“Our spacing in our plants is about 18 inches in the Monterey. For the Cabrillo, for the past three years we have done 14-inch plant spacing and then we did 16. It was fine, and Cabrillo was great.”

Sundance harvests strawberries from March to October.

“We harvest every two days – every single row gets picked twice a week,” Vazquez-Celaya said.

“My yield for my budget is 10,000 crates per acre. That’s what I’m shooting for. Cabrillo will probably do nine, and Monterey will do 11 – if everything goes right.”

But massive yields are not usually a great influencer on profits, Vazquez-Celaya said.

“This year, if you ask any California strawberry grower, is odd. We had a huge peak in June. This year we had amazing yields, but in terms of price, it was not good.

“We have a cooler that had never been at capacity previously. We had to receive berries, and put them in a storage room, and kind of rotate in and out, that is how many berries we had coming in. As far as the price, any grower knows that (high volume) was miserable. We were selling organic berries at about $2.”

– VGN Managing Editor Gary Pullano

Top photo: Jacqueline Vazquez-Celaya is the grower/manager of Sundance Farms’ berry operation in Moss Landing, California. Photos: Gary Pullano

Worker relations keep production buzzing

Everything a grower can do to control yield – and secure profits – that emerges with a stellar crop is put in the mix, said California strawberry grower Jacqueline Vazquez-Celaya.

Some situations “happen naturally to control that.”

The North American Strawberry Growers Association’s Summer Tour visit to Sundance Berry Farms coincided with one of those “natural” occurrences that put the harvest operations into a delay – the first day of school for children of the employees, which meant 60 mothers took time off to attend to their family’s needs, with 40 not returning that day.

“Something so simple as that, and we’re literally missing 60 moms,” Vazquez-Celaya said. “The mom in me thinks that’s awesome that they are going to be taking their kids to the first day of school. But the mom of me who is here, wish they were here, too. I certainly do understand.

“The raspberries and blackberries came in slow, taking away some of our workers, and with the first day of school, we’re dealing with decreasing labor almost every week.”

Vazquez-Celaya touched on a number of approaches Sundance Farms uses to maintain a reliable and satisfied workforce, including child care arrangements and other family-friendly considerations.

“I think we are pretty unique in the way we handle our labor,” she said. “We are exclusive partners with United Way.

Every one of our workers who have children receives a backpack with school supplies. Every single year, every child of our workers gets a brand-new jacket, also donated by another organization.”

The company works with the Special Supplemental Nutrition Program for Women, Infants, and Children (WIC) that provides federal grants to states for supplemental foods, health care referrals, and nutrition education for low-income pregnant, breastfeeding, and non-breastfeeding postpartum women, and to infants and children up to age five who are found to be at nutritional risk.

“All of our returning moms have a very structured program in place to be able to provide food and care to their children while they are working,” Vazquez-Celaya said. “We work with them to provide transportation for medical appointments.”

Making sure transportation is available for that purpose keeps workers in the field on a more predictable basis.

“Previously, our workers would go to a doctor’s appointment and take the rest of the day off. Because most of our employees carpool, and the driver happened to be the one with an appointment, then we would be out five or six workers for that day. So providing transportation for doctors’ appointments has worked out really great because they bring them back here to work.”

Sundance Farms retrofitted a trailer on the property, filling it with home goods and clothing that can be accessed by workers and their families to meet immediate living needs.

“We also raffle off 10 tickets a day to allow people to go in and get things they need for their lives. Things like that we hope are the reason why people want to work here. We have H-2A, but we have over 400 acres and we only have people about 80 H-2A workers – not even half of our workforce. The rest of them are domestic.

“We hope to be a preferred employer so that we can limit the guest-worker program,” she said. “The H-2A people we do have work really great, but it tends to be a very expensive program.

It’s not so much the cost, but where do we put them, with the shortage of housing in this area. We purchased and converted some housing to H-2A but it involved a lot of expense.”

“In terms of the workability of the H-2A program, it’s amazing,” she said. “For the workers, they really come with 100 percent (focus), because for them they are here to make as much money as they can because they know that they are going to go back home.”

Having the structure of a committed workforce helps meet production demands.

“If I have 80 (H-2A) employees, I have 80 employees every day,” Vazquez-Celaya said. “That’s a big change from domestic employees. We may have started with 300 employees on Monday, and the next day it starts going down. This week on Tuesday it went up, then Wednesday was the first day of school. We need to figure out how to make it consistent.”

Government mandates also challenge growers.

“We have added things in California, such as three sick days. Once employees qualify, they can get three sick days in a season where they just have to call in and say ‘I’m sick.’ There’s no excuse or doctor’s note needed. In June, people usually start qualifying, so every day there’s about 20 people who call in sick. Our harvesters use them up. I understand, because everyone has a personal life, but now we have 20 people a day calling in sick and they don’t even have to prove that they’re sick. California legislation makes for it to be a lot to handle every single day.” – VGN Managing Editor Gary Pullano

– VGN Managing Editor Gary Pullano