Mar 27, 2018WeighPack debuts ‘Sleek Inverted’ packager

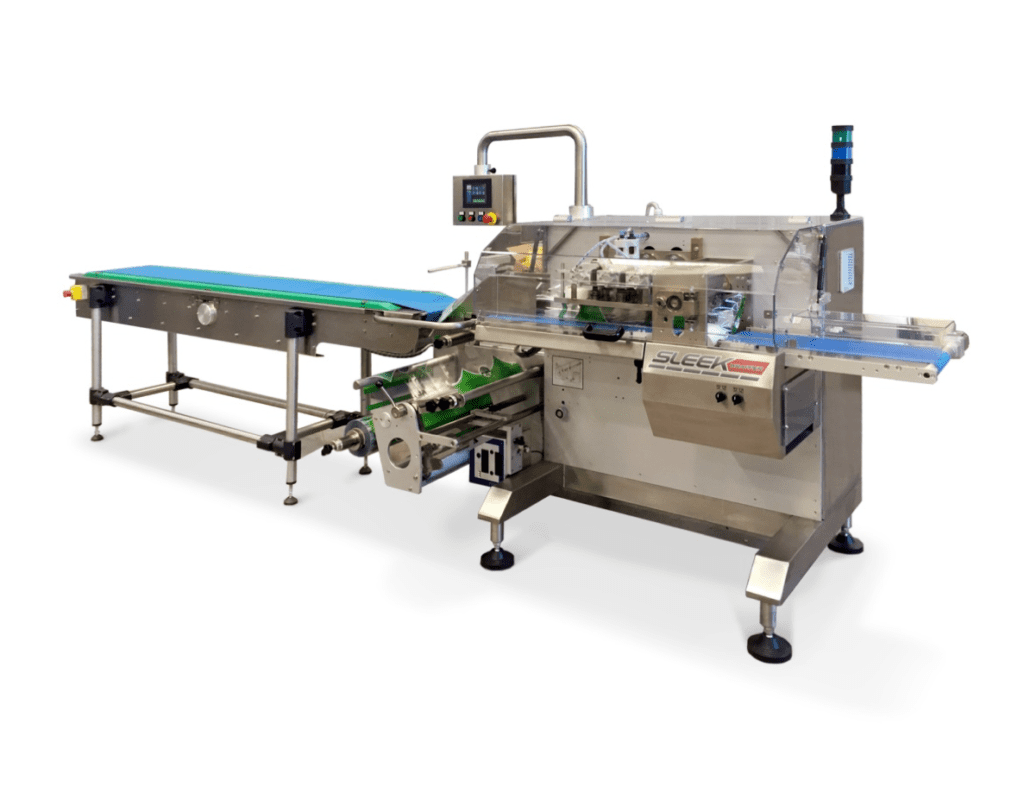

WeighPack has added a new device to its Sleek Wrapper-brand of automatic flow packaging machines.

Flow wrapping is a horizontal packaging process in which product enters the machinery and is wrapped in clear or printed film, according to the company. The result is a tightly-fitted, flexible package with a horizontal back seal and top/bottom vertical seal.

The servo-driven Sleek Inverted is engineered to handle soft, sticky, or multipack products that may be difficult to push with the traditional lug chain design found on most conventional flow wrappers. With the Sleek Inverted, the product is securely carried on top of the packaging film from the former to the cutting head.

The Sleek Inverted produces up to 100 packages per minute with a maximum web width of 19.6” (500 mm) and is also capable of operating on a wide variety of materials including polypropylene, microperf, multilayer laminated, co-extruded, foil films, and more. These flexibility benefits make the Sleek Inverted the perfect flow wrapping solution for many food items.

Standard features include pre-programmed and stored product set up, stainless steel frame construction, user-friendly color touchscreen HMI, auto open/close rotary fin wheel assembly and rotary seal jaws with jam detecting logic.

WeighPack Systems was established in 1991 and since has delivered packaging systems to more than 30 countries.

For more information, visit www.sleekwrapper.com.

Above: Sleek Inverted. Photo: WeighPack