Jan 5, 2026Spray drones: best practices for specialty crop use

Seeking to improve efficiencies, growers are turning to county Extension agents and university researchers to learn more about using drones for spraying and other chores in fields, orchards and vineyards.

While drones can supply aerial imagery of tree fruit, grapes, berries, melons and vegetables, growers

want to know how the tech compares to ground sprayers.

When it comes to applications, a specialty crop grower producing carrots and pumpkins has different needs than growers of apples or peaches, said Michael Reinke, Michigan State University (MSU) viticulture specialist and integrated pest management educator for fruits and vegetables.

While air or drone applications for corn or soybeans may require a quart of water per acre, once a grower

grows lettuce, labels require up to five gallons an acre, said Reinke, who conducts research on spray drones for specialty crops.

“One of the challenges we’ve been hearing is lack of adoption, because you hear these drones are being used more in the row crop space on large acres,” he said.

In specialty crops, drones must spray smaller crops, smaller fields, and more complex field structures and plant canopies, Reinke said.

Assembly required

Proper drone assembly is crucial.

“Setup matters, not just for the flight of the drone but actual application, because these are sprayers,” Reinke said. “New spray drones are moving away from hydraulic nozzles to rotary atomizers, but the same concept applies: using the right size droplets, at the right speed and the right height.”

Before purchasing, growers should understand drone use-cases.

“Keep in mind that physics don’t change because you own a drone,” said Mark Ledebuhr, principal consultant with Application Insight. “You hear a lot of claims about productivity and coverage and all kinds of things. If it sounds too good to be true, it might be.”

Ledebuhr and his team at Application Insight, a spray drone consulting firm based in Lansing, Michigan, recommends growers keep this simple equation in mind: Gallons per acre equals gallons per minute, times miles per hour, times swath width.

Careful monitoring of drone spraying outcomes and daily pre- flight calibrations are necessary. Though drone controllers provide high-resolution images, it doesn’t always mean the spray mix penetrated the canopy properly. Because the air from the prop downwash interacts with spray droplets, aerial applicators should measure the actual spray swath, or width of application, through string analysis, Ledebuhr said.

“If you wind up in court [regarding spray drift] and you have the data, the jury is going to be a lot more

understanding,” Ledebuhr said. “If you don’t have that data, there’s going to be a professional witness who’s going to eat your lunch, dinner and breakfast. It’s important to know what you’re doing. Spraying and praying doesn’t cut it.”

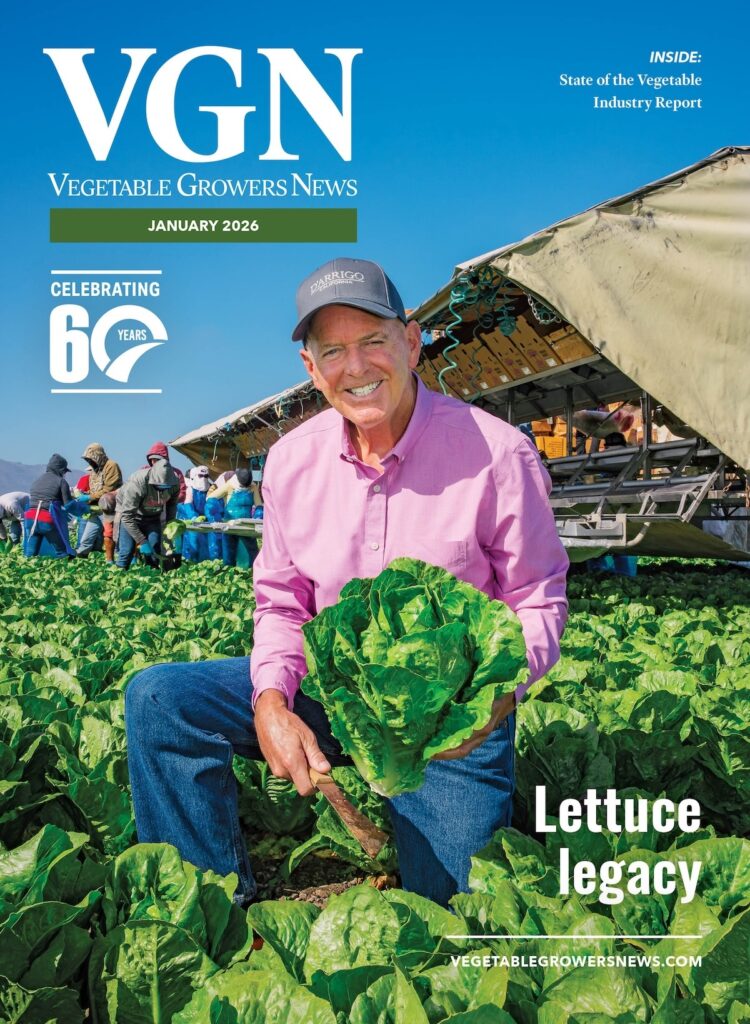

University researchers and others study how drones can help growers spray in fields, orchards and vineyards. Photo courtesy of Michael Reinke.

Different uses

While drones are a practical tool for treating specialty crops, it’s important to note not every situation will result in a successful treatment, said Briana Layfield, president and founder, AgBee, a Temecula, California, drone provider.

“Newer models vary in tank capacity, output capabilities and function, but each model has a use

case where it tends to work best,” Layfield said. “It’s highly dependent on your particular operation what’s going to work best for you.”

Smaller-capacity drones typically apply from 5 to 10 feet above vineyard canopies, while larger units achieve better coverage when flying 7 to 12 feet over the canopy. At 5 to 7 gallons per-acre (GPA) application rates, a drone with a 10-liter tank can average 12 to 15 acres per day. Larger 16-liter drones can cover 18 to 20 acres a day, and 60-liter units can average 30 to 70 acres a day.

“We found there’s a slight increase in drift potential,” Layfield said. “However, the downward prop wash effect and optimal application height with optimal droplet size increases penetration overall. The majority of specialty crop applications require a minimum of 5 to 10 GPA, depending on the product label.”*

Ground-based airblast sprayers can push droplets several rows off target. Intelligent sprayer systems

cut that drift substantially, while drones show virtually no drift beyond one or two rows, Reinke said.

Neither drones nor intelligent sprayers work well for alternate row middle spraying in orchards, with drones rating below the 10% cutoff in Reinke’s trials.

“Once you get out there to the very far end of the drift pole I added to the project, you’re still seeing some level of drift on the intelligent sprayers — much lower than the standard conventional air blast rig, but the drone is lowest of all,” Reinke said.

Drones require new ways of thinking.

“Think of drones not like a helicopter,” Reinke said. “It’s not like an airplane. These things are flying slow, andthey don’t operate like manned aircraft. Think of them like air blast sprayers, but now it’s over the crop, spraying down.”

*Editor’s note: Growers must always consult the product label before applying a crop protection product. Remember, the label is the law.

Top photo: As drone use expands in field crops, Michigan State University researchers are studying how the technology can be adapted for specialty crop production. Photo courtesy of Ag-Bee.

— Doug Ohlemeier, Contributing Writer