Aug 1, 2018Irradiation an option for vegetable processing, food safety

Food irradiation technology has been around for more than 50 years to kill pathogens, although it’s not used widely throughout the processing industry.

Now, a growing firm called ScanTech Sciences is marketing its irradiation services for use with fresh produce.

ScanTech Sciences is building its first facility in McAllen, Texas’ Rio Grande Valley ECP Center, and is in the process of starting its commercial operations this summer.

The facility will be able to process between 120-160 cases of produce per minute, said Lindsay Eierman, ScanTech Sciences’ marketing manager. The company plans to open other facilities in ports of entry, such as New York/New Jersey and Nogales, Arizona, she said. Eventually, the company’s plans are to expand to areas such as of secondary import and export markets, such as Savannah, Georgia; Houston, Texas; and California.

“It’s been proven it can reduce the count of salmonella and listeria by more than 99.99 percent,” Diez-Gonzalez said. “It’s capable of killing viruses. It also helps to reduce microorganisms that could have an influence in spoilage.”

The technology, however, isn’t widespread in its use.

“Although the technology has been around for quite some time, it was not economical for use as a commercial application until the early 2000s,” Eierman said. In 2004, Australia shipped half a ton of irradiated mangoes to New Zeeland, which was the first international use of food irradiation.

Food irradiation is approved by dozens of reputable organizations, including the U.S. Department of Agriculture, the Food and Drug Administration, the Centers for Disease Control, the American Medical Association, and the United Nations World Health Organization, Eierman said – it’s also currently used as a postharvest food process in over 40 countries.

But there is room for the process to grow.

“There are two primary reasons that food irradiation is not more widely used,” Eierman said. “The first issue is intellectual property and investment. The technology is very complicated and requires expertise in nuclear engineering, mechanical engineering, and food science.”

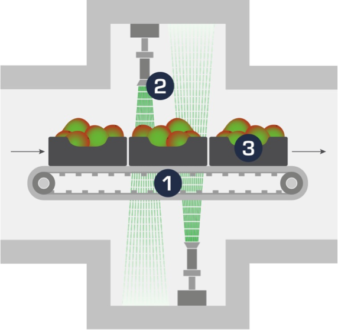

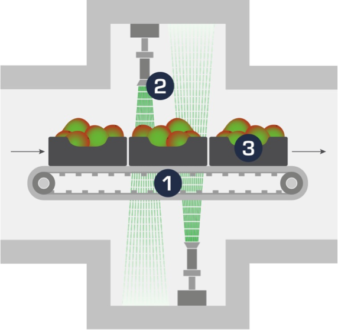

Food irradiation can include the use of gamma rays, X-rays or electron beams, called e-beams. ScanTech Sciences’ patented form of e-beam food irradiation is Electronic Cold-Pasteurization, so-called because it allows product to be kept cold throughout the process. Not breaking the cold chain of storage is an added value for food processors.

The second reason food irradiation is uncommon, she said, is simply capacity. The technology is expensive, and Eierman said there have not been very many successful food irradiation ventures.

But that isn’t to say that food irradiation is rare.

Eierman said about a third of spices imported into the United States are irradiated, as are many imported tropical fruits, such as guava, dragon fruit, persimmons and mangos. Many food products consumed by NASA astronauts are irradiated to prevent sickness, according to the FDA’s website.

Eierman said food irradiation could be a good fit for processing fresh produce.

“Electronic Cold Pasteurization is a great solution for fruit, vegetables, herbs, spices and ready-to-eat (fresh-cut) commodities such as sliced apples,” she said. “It is particularly beneficial for commodities with short shelf life (such as berries or leafy greens), commodities with a high incidence of pests (such as peaches, which have the plum curculio), and commodities that are susceptible to contamination with pathogens (such as Listeria monocytogenes in cantaloupe or E. coli in lettuce).” Irradiation is useful for not only for sanitizing foodstuffs but also eradicating pests.

One example of this is U.S. blueberry exports. Blueberry maggot fly larvae in the eastern U.S., and their presence in blueberries restricts exports of the berries to some countries trying to avoid infestation by the blueberry maggot fly. As certain chemical fumigants are phased out, irradiation is among tools being examined in a project led the U.S. Highbush Blueberry Council.

Eierman said her company’s technique of e-beam food irradiation could serve as a safe, chemical-free alternative to methyl bromide fumigation, which remains in widespread use despite known downsides.

“Methyl bromide is a chemical fumigant that has been used for decades on imported and exported commodities as a pest control mechanism,” Eierman said. “Unfortunately, methyl bromide is a harmful ozone-depleting substance. The Montreal Protocol of 1987 was an international treaty that attempted to phase out the use of methyl bromide. However, methyl bromide remains in use because it is one of the few substances that provides effective pest control.”

Her company also hopes to combine its food irradiation services with integrated logistics, transportation and information services.

“These services reduce compliance costs associated with the Food Safety Modernization Act (FSMA),” she said. The Produce Safety Rule allows an exemption for produce that is going to a kill-step process. Electronic Cold-Pasteurization is a viable solution for meeting this exemption.

“ScanTech Sciences is eager to transform the food industry by providing safer, higher-quality produce,” Eierman said.

– Stephen Kloosterman, VGN Assistant Editor

Top photo: ScanTech’s Rio Grande Valley ECP Center near McAllen, Texas.